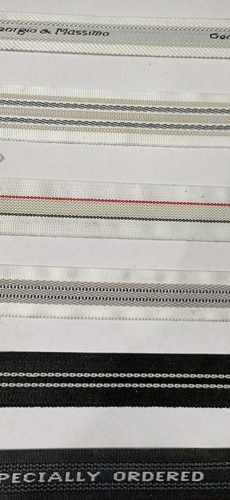

Gripper tapes

Gripper tapes Specification

- Finishing

- Smooth

- Usage & Applications

- Textile industry, conveyors, packaging machines

- Diameter

- Standard

- Dimension (L*W*H)

- Custom sizes available

- Type

- Gripper Tape

- Material

- Rubber, Synthetic Compound

- Size

- Multiple sizes

- Weight

- Lightweight

- Color

- Grey

- Customization

- Available as per requirement

- Adhesive Type

- Double-sided, Non-adhesive options available

- Tensile Strength

- High durability for industrial applications

- Surface Texture

- Knurled / Textured for enhanced grip

- Elongation at Break

- > 300%

- Shelf Life

- 12 Months

- Hardness

- 60-80 Shore A

- Thickness

- 1.5mm to 4.0mm

- Temperature Resistance

- Up to 80°C

Gripper tapes Trade Information

- Minimum Order Quantity

- 3000 Meters

- Delivery Time

- 15 Days

About Gripper tapes

Redeem your workflow efficiency with our preeminent Gripper tapes, available in double-sided adhesive and non-adhesive options. Remarked for high tensile strength and temperature resistance up to 80C, these tapes feature a knurled, textured surface, ensuring exceptional grip and reliability. Ranging from 1.5mm to 4.0mm in thickness and manufactured from premium rubber and synthetic compounds, they withstand elongation at break over 300%. Spotlighted as a masterpiece in industrial durability, they suit textile, conveyor, and packaging sectors. Affordable, lightweight, and customizable in size, color, and dimensions, these tapes represent Indias leading manufacturer, supplier, and wholesaler distinction.

Ideal Applications & Advantages of Gripper Tape

Gripper tapes are eminently suitable for textile machinery, conveyor belts, and packaging units, enhancing operational security and precision. Their textured surface delivers improved grip and minimized material slippage, making them invaluable for industrial sites requiring reliable transfer and handling. Multiple size and finish options allow for tailored placement, providing an affordable yet effective solution for industrial applications. Customized dimensions further ensure seamless integration and adaptability, maximizing the advantage for specialized tasks and machines.

Certifications & Timely Delivery Details

Our Gripper tapes carry essential industry certifications, guaranteeing safety, durability, and quality. Dispatching from major Indian FOB ports, we offer rapid processing times to expedite delivery and exchange, ensuring your procurement requirements are met promptly. Orders are generally delivered within the stipulated timeframes, maintaining material integrity through careful handling and packaging. Customers benefit from transparent delivery schedules and support, facilitating hassle-free acquisition of our certified, high-quality industrial tapes.

Ideal Applications & Advantages of Gripper Tape

Gripper tapes are eminently suitable for textile machinery, conveyor belts, and packaging units, enhancing operational security and precision. Their textured surface delivers improved grip and minimized material slippage, making them invaluable for industrial sites requiring reliable transfer and handling. Multiple size and finish options allow for tailored placement, providing an affordable yet effective solution for industrial applications. Customized dimensions further ensure seamless integration and adaptability, maximizing the advantage for specialized tasks and machines.

Certifications & Timely Delivery Details

Our Gripper tapes carry essential industry certifications, guaranteeing safety, durability, and quality. Dispatching from major Indian FOB ports, we offer rapid processing times to expedite delivery and exchange, ensuring your procurement requirements are met promptly. Orders are generally delivered within the stipulated timeframes, maintaining material integrity through careful handling and packaging. Customers benefit from transparent delivery schedules and support, facilitating hassle-free acquisition of our certified, high-quality industrial tapes.

FAQs of Gripper tapes:

Q: How can the Gripper tape be customized for specific industrial needs?

A: Gripper tapes can be tailored by requesting specific thicknesses, dimensions, surface textures, and adhesive types to precisely match your application requirements.Q: What sites and machinery benefit most from Gripper tape usage?

A: Textile machinery, conveyor systems, and packaging machines gain optimal performance and grip reliability by incorporating these tapes into their operational setup.Q: Where are the tapes dispatched from, and how is delivery managed?

A: Our tapes are dispatched from major Indian FOB ports with structured delivery management to ensure safe, prompt arrival at your location.Q: When is it advisable to exchange or replace Gripper tapes?

A: Exchange or replacement is recommended when tapes show signs of wear, reduced grip, or after the 12-month shelf life to retain efficiency.Q: What is the benefit of the knurled/textured surface on these Gripper tapes?

A: The enhanced knurled/textured surface dramatically improves material grip, minimizing slippage and boosting operational safety.Q: How does the certification process assure product quality?

A: Certifications confirm adherence to industrial standards, verifying tensile strength, temperature resistance, and material durability for dependable use.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Gripper Tapes Category

Gripper Tapes

Price 7 INR / Meter

Minimum Order Quantity : 3000 Meters

Color : Blue, White, Cream and Grey

Product Type : Interlinings

Length : 25 to 100 Meter (m)

Width : 50.8 Millimeter (mm)

Trouser Gripper Black Tape

Price 7 INR / Meter

Minimum Order Quantity : 3000 Meters

Color : Black and Red

Product Type : Gripper Tape

Length : 25 to 100 Meter (m)

Width : 50.8 Millimeter (mm)

Trouser Grippers Tape

Price 7 INR / Meter

Minimum Order Quantity : 3000 Meters

Color : Black, Grey and White

Product Type : Interlinings

Length : 25 to 100 Meter (m)

Width : 50.8 Millimeter (mm)